Core Count: 3P, 4P

Category:Male

Direction:180°

Applications: Power, Signal

Straight plastic assembly screw type:

Flexible assembly and convenient maintenance: The screw type design supports rapid on-site assembly and cable replacement. Compared to fixed and molded connectors, if the cable is damaged or the equipment needs to be modified, the screws can be removed and the cable can be re-secured without the need for an overall replacement of the connector. This significantly reduces equipment maintenance costs and downtime, and is suitable for equipment modification and batch deployment scenarios. The connection is firm and has strong vibration resistance: The nickel-plated brass screw locking structure has high torsional strength and is less likely to experience slippage or cracking. Combined with the screw-pressing terminal connection method, it can reduce the risk of terminal loosening caused by equipment vibration. It is mainly used in on-site connection scenarios of industrial AC power supplies, such as the power supply connection between servo motors and control cabinets in ordinary machine tools and automated production lines. The screw assembly type can meet the on-site wiring requirements of the equipment.

|

Product model

|

Core

|

Rated current

|

Rated voltage

|

Wire gauge / Dimension

|

||

|

A/C

|

D/C

|

AWG

|

mm²

|

|||

| MC12SF-03N1LJMNR701 |

3

|

4A

|

250V

|

250V

|

22

|

0.34

|

| MC12SF-04N1LJMNR701 |

4

|

4A

|

250V

|

250V

|

22

|

0.34

|

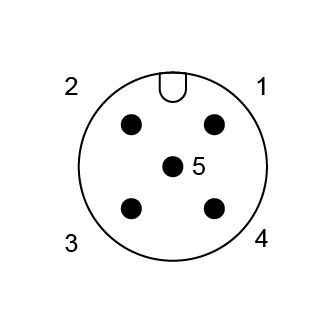

| Core | 2A | 3A | 4A | 5A |

| male end |

|

|

|

|

| 6A | 8A | 12A | 17A | |

|

|

|

|

|

|

| 4B | 5B | 3C | 4C | |

|

|

|

|

|

|

| 5C | 6C | 4D | ||

|

|

|

|

||

| Core | 2A | 3A | 4A | 5A |

| female connector |

|

|

|

|

| 6A | 8A | 12A | 17A | |

|

|

|

|

|

|

| 4B | 5B | 3C | 4C | |

|

|

|

|

|

|

| 5C | 6C | 4D | ||

|

|

|

|

|

The connector must not be plugged or unplugged under load. Failure to follow the instructions and improper use can result in personal injury.

The development of the connector is aimed at being applied in factory engineering, control and electrical equipment construction. Users are responsible for checking whether the connector can also be used in other applications.

Connectors used in circuits with dangerous voltages that cause electric shock must be installed and used only by personnel who have received training in electrical engineering, or under their supervision, while taking into account the applicable regulations and standards.

Users must take appropriate security measures to ensure that the connectors do not accidentally disconnect.

When installing, apply moderate force and use the special tool to tighten the nuts. Avoid excessive force to prevent the shell from deforming or the pins from bending. Ensure that the plug and socket are fully engaged. Do not power on the device when not locked in place to prevent arc discharge due to poor contact.

The plug connectors with an enclosure protection rating of IP67 and IP68 are not suitable for use in water. When used outdoors, the plug connectors must be protected against corrosion separately. For further information on IP protection ratings, please refer to "Technical Information".