The housings of this series of connectors are mostly made of materials such as nickel-plated brass. The contacts are gold-plated. The basic protection level reaches IP67, enabling stable operation within a wide temperature range of -40℃ to +85℃. It is resistant to oil and vibration, has low contact resistance and excellent insulation performance. It is commonly used for devices such as photoelectric switches and encoders, and is widely applied in industrial automation, robotics, and new energy fields. It can stably transmit low-voltage sensor signals. Some models with shielding layers or compatible with specific protocols can also achieve high-speed data transmission, effectively suppressing electromagnetic interference.

The M8 A coding connector is a commonly used type of connector in the M8 series, designed for basic signal transmission. It is frequently used for signal transmission in devices such as vision sensors and pressure sensors, and is widely applicable in industrial automation, new energy, and robotic arms and other scenarios.

It is widely applied in the field of industrial automation. Devices such as the conveyors and sorters in warehouses, as well as the joints of industrial robots and servo motors for motion control, all adopt this technology.

The M8 D coding connector is a 4-core shielded type with a protection level of IP67. It supports 100Mbit/s Ethernet transmission and PoE power supply, and is mainly used for connecting small sensors, vision systems and other devices in industrial automation.

Its contact points are mostly made with gold plating process, with contact resistance less than 5mΩ and insulation resistance exceeding 100MΩ. This can reduce losses in signal and power transmission. The shielded type model features a 360° full shielding structure, which can effectively suppress EMI and RFI electromagnetic interference and ensure signal integrity. The D-coded model can also achieve high-speed data transmission of 100Mbit/s. The 8-core model is compatible with PROFINET and other bus communication, meeting the high-speed transmission requirements of industrial Ethernet.

Supports standard voltage scenarios ranging from 24V to 30V. Some models can cover low voltage signals below 50V being transmitted to 250V industrial equipment power supply scenarios. The rated current ranges from 0.5A to 4A, capable of meeting various electrical requirements such as sensor signal transmission and power supply for small actuators.

The basic models generally reach the IP67 protection level, which can achieve complete dust-proof and short-term water immersion. Some special models can reach levels such as IP68 or IP69K, which can withstand high-temperature and high-pressure rinsing and are suitable for scenarios such as equipment cleaning in the food and beverage industry, and humid environments in the chemical industry. The shells are usually made of materials such as nickel-plated brass, oil-resistant TPU, etc., and are equipped with epoxy resin sealing components. They also have excellent oil resistance and chemical corrosion resistance.

Resistant to extreme temperature differences ranging from -40℃ to +85℃. After undergoing temperature cycling tests, the material shows no cracking and no performance degradation. It can be used for both northern cold outdoor equipment and industrial high-temperature workshops.

After undergoing vibration tests with a frequency range of 10 - 500 Hz and an amplitude of 0.35 mm, some models can withstand long-term vibrations at an acceleration of 50g. When used in high-frequency vibration equipment such as industrial robot joints and conveyor lines, they can maintain stable connections without any signal interruption.

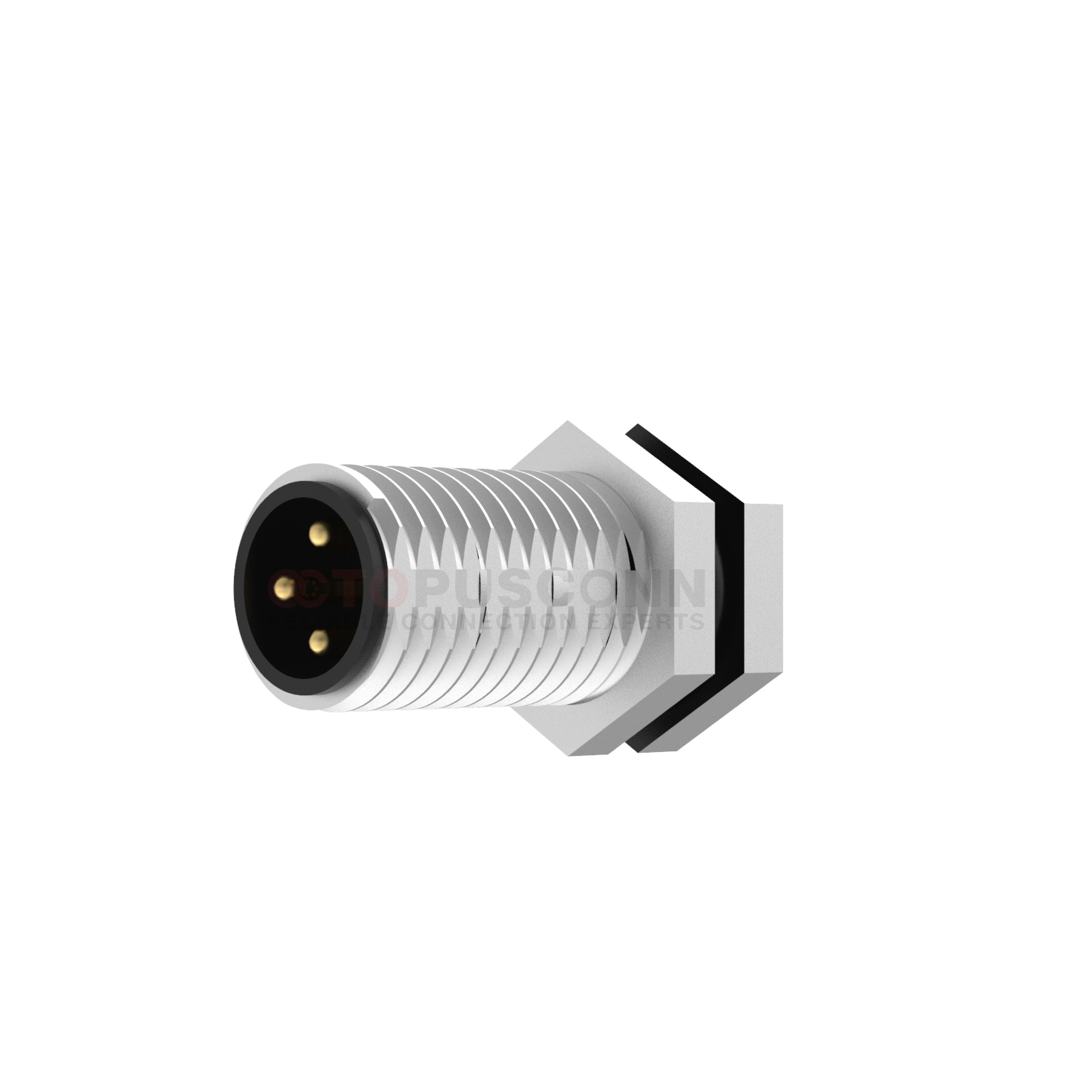

It adopts a standard M8×1.0 thread locking structure, with a tightening torque of up to 0.5 - 0.8 Nm. Combined with the anti-misinsertion design of the female head notch and the male head protrusion, it can not only prevent connection errors from damaging the equipment, but also prevent loosening caused by vibration. Some manufacturers also adopt anti-rotation thread profile technology, raising the plug-in and unplugging stability to the 500-cycle standard.

The mechanical lifespan of the product is generally ≥ 500 times of insertion and removal, and the change in contact resistance is still less than 10mΩ. After undergoing a 48 - 72 hour neutral salt spray test, the metal components show no obvious corrosion, which can reduce the cost of frequent maintenance and replacement in industrial scenarios.

It is available in two forms: straight head and curved head. The curved head can optimize the wiring path in scenarios with limited space. There are also various installation methods such as line-to-line, line-to-board, and PCB board mounting. Combined with flange plates and other structures, it can be firmly fixed on the equipment casing or control cabinet, meeting the installation requirements of different devices.

It supports various wiring methods such as welding and crimping. Among them, the crimping type adopts cold crimping technology, which does not require high-temperature operations. The wiring can be completed within a few seconds without any risk of short circuit, significantly improving the efficiency of on-site wiring and maintenance, and also reducing the construction difficulty.

The number of cores ranges from 3 to 8, covering various specifications. Different core counts are suitable for different scenarios. For example, 3 cores are suitable for three-wire sensors, 4 cores are used for encoder control, 5 cores are applicable for multi-channel pressure transmitters, and 8 cores are used for high-density bus communication. In addition, there are various encoding models such as A/B/D, which can match different industrial protocols. At the same time, the manufacturer also provides customized services such as core count and cable length, and can meet the diverse connection requirements of sensors, medical devices, and new energy equipment.