一、The core feature of the M16 connector: From the technical parameters, its industrial compatibility capability

The "industrial-grade advantage" of the M16 connector is not an abstract concept but is determined by specific technical parameters, structural design and material selection. Taking the classic M16 angled hole head cable connector (with 8 pins and IP67 protection level) in the industry as an example, its characteristics perfectly meet the strict requirements for connections in industrial scenarios. This can be further analyzed from the following aspects:

1.Protection performance: The "first line of defense" against harsh environments

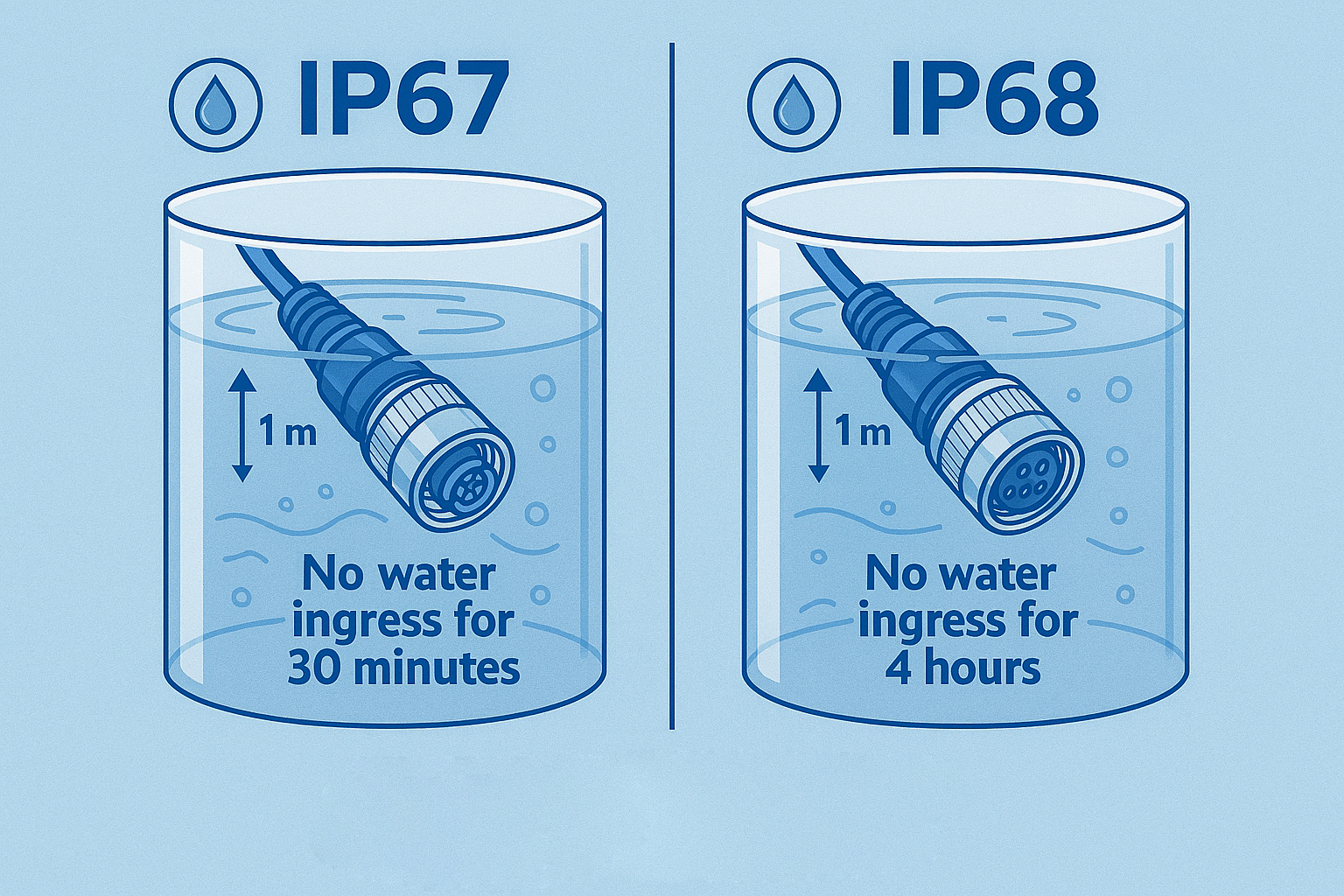

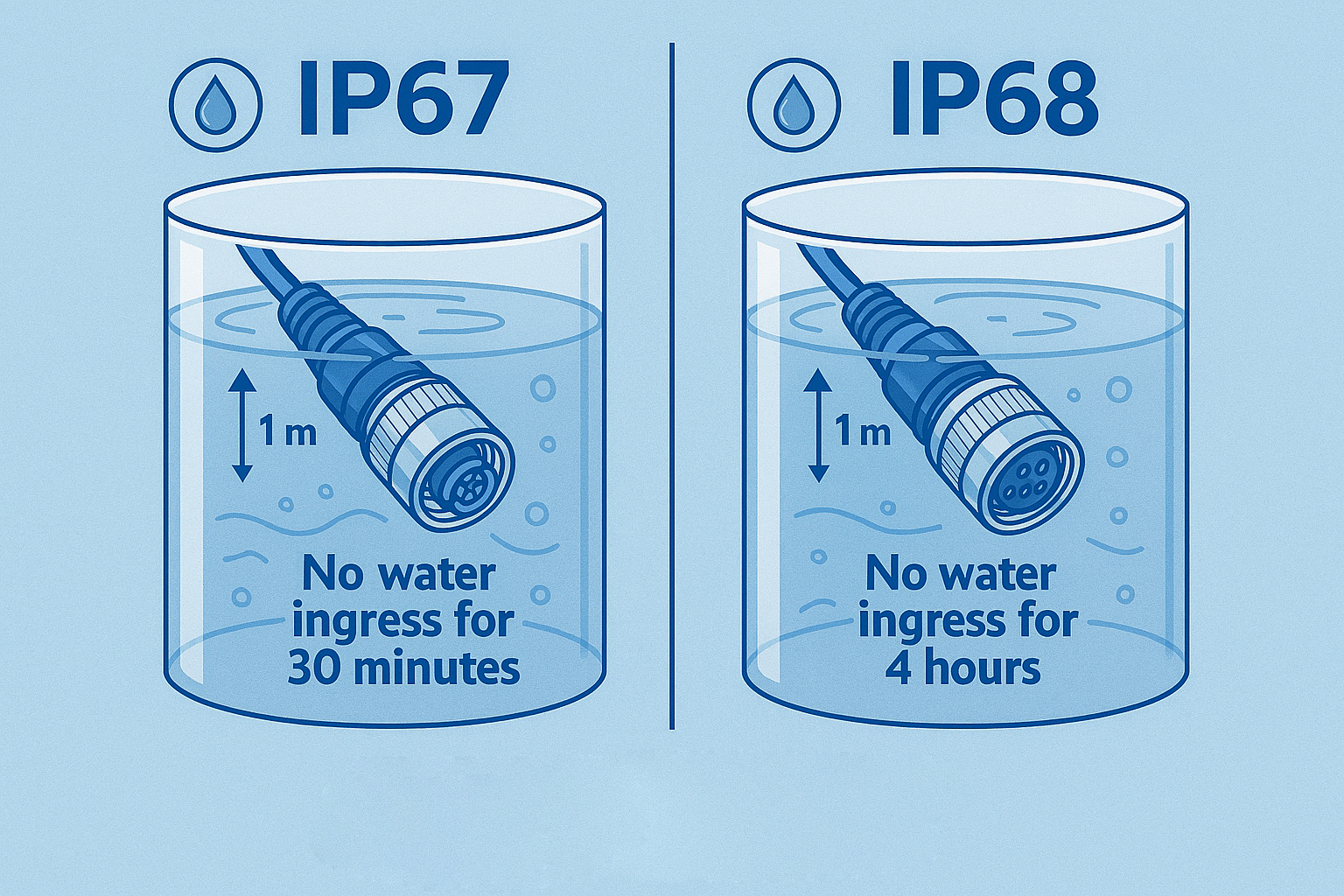

In industrial scenarios, dust, oil stains, water mist and other impurities are the main threats to connectors, and the IP protection level directly determines the environmental tolerance of the connectors. The reference model mentioned above clearly indicates that the protection level is IP67, meaning it can achieve "complete dust prevention + short-term immersion in water (no water ingress within 30 minutes at a depth of 1 meter)", and can be directly applied to outdoor lighting, industrial robot wiring boxes, power equipment compartments and other scenarios where exposure to water vapor or dust is common; some upgraded M16 connectors (such as the outdoor-specific models) even support IP68 protection, which can achieve "long-term protection against deep water immersion", and are suitable for marine equipment, agricultural irrigation machinery and other scenarios where water contact is long-term.

Octopusconn Technology Extension:

The M16 connector series of OCTOPUSCONN covers protection levels from IP67 to IP68. The IP68 model has passed the 4-hour immersion test in 1-meter water depth (in accordance with the waterproof standards published on hktdc.com), and all products have passed salt spray tests for more than 500 hours. It is particularly suitable for strong corrosive environments such as chemical and marine engineering. At the same time, it complies with the RoHS environmental protection standard, balancing environmental adaptability and sustainability.

Comparison diagram of IP67 and IP68 protection tests for M16 connector

2. Electrical performance: Ensuring stable transmission of signals and power

Industrial equipment has extremely high requirements for "zero failure" in electrical connections. Any signal interruption or unstable current can lead to the halt of the production line. The electrical parameters of the M16 angled hole head cable connector are commendable:

- Rated voltage: 60V, Rated current: 5.0A: Compared to the traditional 3.0A model, it can be compatible with higher-power actuators (such as small motors, heating modules), meeting the "high-power distributed control" requirements in industrial automation.

- Insulation resistance ≥ 10¹⁰ Ω: Significantly reduces the risk of leakage, preventing equipment short circuits caused by insulation failure;

- Shielding capability (shielding ring design): Effectively resist electromagnetic interference (EMI). In scenarios with a high density of 5G base stations and industrial Internet of Things (IIoT) devices, it can ensure the accuracy of data transmission (such as the real-time temperature and pressure data collected by sensors without deviation).

3. Mechanical structure: Suitable for complex installations and high-frequency operations

The installation space in industrial sites is often limited, and connectors may need to be frequently plugged and unplugged (such as during equipment maintenance or component replacement), which imposes dual requirements on the "flexibility" and "durability" of the mechanical structure:

- Angle design - 2-24-core coding option: The reference model adopts a 90° angle connector structure, which enables flexible wiring in narrow spaces (such as inside equipment cabinets) and avoids excessive cable bending.

- 500 insertion and removal cycles: Some upgraded M16 connectors (such as the new aviation plugs mentioned on Taobao Digital Network) have a plug-and-unplug lifespan of up to 3,000 - 5,000 times, far exceeding the regular usage frequency in industrial settings (the number of plug-and-unplug operations within a typical equipment maintenance cycle is generally ≤ 100 times). After long-term use, they can still maintain stable contact.

- Screw locking device: Compared to the snap-locking type, the connection strength of the screw locking design is higher. It is less likely to loosen in scenarios with frequent vibrations (such as rail transit equipment, heavy machinery), and some models can even withstand tens of kilograms of tension (in line with the mechanical strength standards published by TXGA).

Detail drawing of the mechanical structure of the M16 connector (angle design and locking device)

二、Industrial application adaptation of M16 connectors: From requirements to solutions

The features of the M16 connector are not just theoretical concepts, but are precisely designed to address the pain points in various industrial scenarios. By combining the application logic of the reference models with the actual cases of Octopusconn, the core application scenarios can be summarized as follows:

1. Industrial Automation: The "Bridge" Connecting Sensors and Actuators

In an automated production line, sensors (such as photoelectric sensors, proximity switches) need to transmit signals to the controller in real time, while actuators (such as cylinders, small motors) rely on stable power supply. The IP67 protection and shielding function of the M16 connector precisely addresses these two major pain points:

- Dust and water resistance: To prevent the connectors from being damaged by metal debris and cutting fluids in the production workshop;

- Anti-interference: In environments with strong electromagnetic fields such as those of frequency converters and servo motors, ensure that the sensor data remains undistorted.

2.New Energy and Rail Transit: "Reliable Assurance" in Extreme Environments

New energy equipment (such as photovoltaic inverters and energy storage battery cabinets) is exposed to the elements for long periods, facing challenges such as high temperatures, heavy rain, and lightning strikes; while rail transit equipment needs to withstand high-frequency vibrations and temperature variations. The high protection, temperature resistance, and vibration resistance characteristics of M16 connectors become crucial:

- The working temperature range is from -40℃ to 85℃, which can cope with most outdoor climates.

- It can withstand the high-frequency vibrations of the rail transit system and has been applied in the signal control system of urban subways and the blade sensors of a certain wind power project.

3. Outdoor and Special Scenarios: The Waterproof and Durable "All-Rounder"

In outdoor construction, stage performances, and marine equipment scenarios, the "waterproofness" and "durability" requirements for connectors are even higher. The IP67 protection and high-strength material of the M16 connector have significant advantages in such scenarios:

- M16 aviation plug, with a nickel-plated brass housing (anodized finish), highly durable and resistant to pressure. It can still function properly after falling from a height of 2 meters. It is suitable for temporary power wiring in outdoor construction.

- The M16 connector launched by Octopusconn for the marine environment features a corrosion-resistant coating against seawater and is equipped with IP67 waterproof design. It can be used continuously for over 5 years in marine salt spray environments and has been integrated into the deck lighting system of a certain marine equipment manufacturer.

三、Selecting M16 connector: Why is OCTOPUSCONN recommended?

Octopusconn, as a domestic high-tech enterprise that has been deeply engaged in the connector field for 10 years, has become the preferred partner for industrial customers with its "customization capabilities + localized services + strict quality control". Its core advantages lie in three aspects:

1. Technical strength: Full-scenario coverage from standard to customization

Octopusconn has a research and development team of over 20 people. It has accumulated more than 20 design patents and can provide:

- Customized solutions: For special scenarios (such as underwater equipment, high-temperature furnaces), customizable features include the number of cores, high-temperature resistant ceramic casings, and anti-corrosion coatings. Samples can be delivered within the shortest 7 days (e.g., the "anti-flooding M16 connector" customized for food machinery, capable of withstanding 100℃ high-pressure water flow cleaning and meeting food industry hygiene standards).

2. Quality control and certification: "Quality Assurance" that complies with international standards

Octopusconn has established a strict quality management system, and all products have passed:

- ISO 9001 quality management system certification, ISO 14001 environmental management system certification;

- It holds the CE international certification. Among them, the insulation resistance and withstand voltage of the M16 series connectors exceed the industry standards by more than 10%.

- For each batch of products, 100% conduction tests, sealing tests and appearance inspections are conducted. The defect rate is controlled below 50 ppm (much lower than the industry average of 100 ppm), ensuring long-term stable operation.

3. Service capability: Localized response and full-cycle support

As a domestic enterprise, Octopusconn can offer more efficient services:

- Delivery speed: The standard M16 connector is in ample stock and will be shipped within 48 hours after placing an order. The customized version can be delivered in batches within the shortest 14 days, meeting the urgent production needs of customers.

- Technical Support: The 24-hour FAE team provides on-site installation guidance and troubleshooting services. For example, they optimize the "M16 connector wiring scheme" for new energy customers, helping them reduce installation costs and the difficulty of subsequent maintenance by 20%.

- After-sales guarantee: All products come with a one-year warranty. In case of any quality issues, solutions will be provided within 48 hours to ensure that the production process of the customers is not affected.

If you are choosing M16 connectors for your industrial projects, whether it's for bulk purchases of standard models or custom requirements for specific scenarios, you can contact OCTOPUSCONN:

- Official website:https://www.octopusconn.com/

- Telephone:+86 18925497513

- Address:Room 611, Times Cloud Valley, No. 1 Dongda Road, Shatou Community, Chang'an Town, Dongguan City, Guangdong Province

Octopusconn will focus on "reliable connection" and offer you a complete solution covering the entire process from selection consultation to after-sales maintenance, helping industrial equipment operate efficiently and stably.