Choosing the wrong number of cores = a waste of effort? Unveiling the core logic behind the M16 selection.

In scenarios such as industrial automation, sensor connection, and energy equipment, the core count selection of M16 connectors directly determines transmission efficiency, device compatibility, and system stability. Many engineering purchasers tend to fall into the misconceptions of "the more cores, the better" or "blind matching" during the selection process, which ultimately leads to connection failures, resource waste, and even equipment damage.

Octopusconn, as a professional brand specializing in industrial connectors, leverages its years of technical expertise and global project service experience to deeply understand the varying core number requirements of M16 connectors in different industries. This article, based on actual application cases in industrial scenarios, will explain the selection logic of M16 connectors ranging from 2 cores to 24 cores from three dimensions: core function positioning, selection principles, and avoidance of pitfalls. It will also share the core advantages of Octopusconn's full range of M16 products, helping you precisely match your needs and avoid any selection pitfalls.

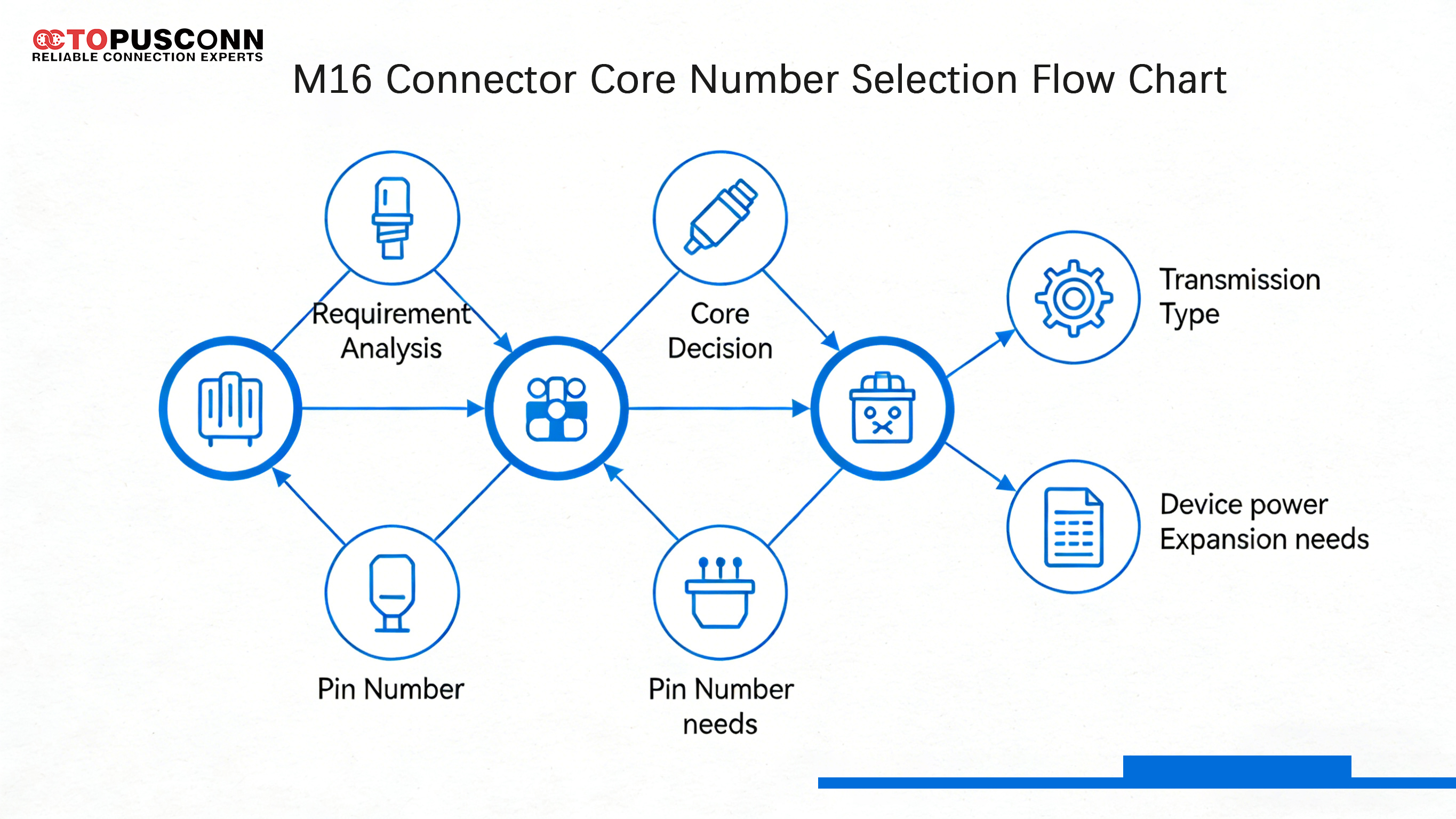

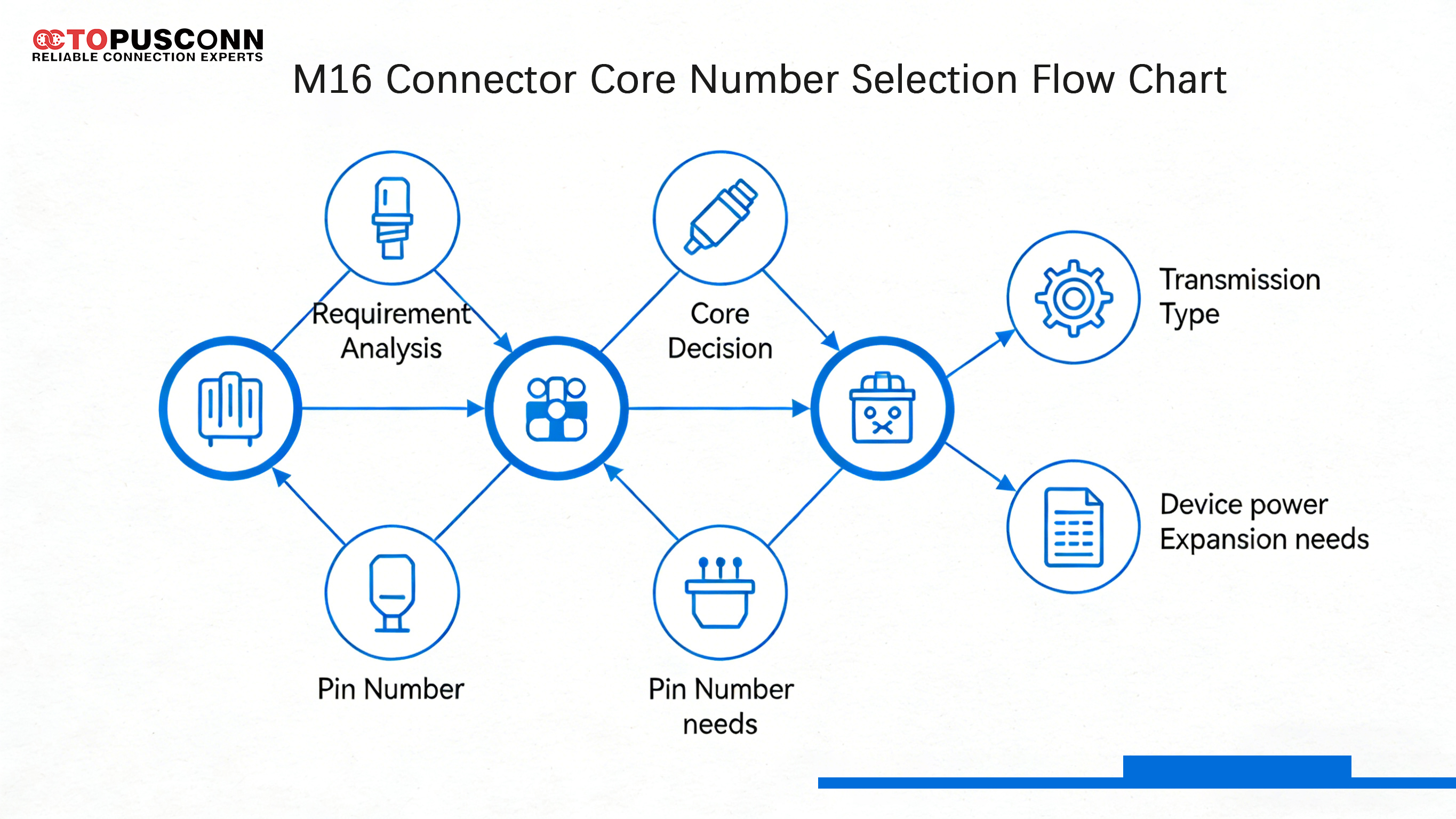

Flowchart of the entire process for selecting the number of cores for M16 connectors

Core positioning of each pin of the M16 connector: Precise matching for different scenarios

1. 2PIN M16 connector: Preferred choice for basic power transmission

- Main purpose: Only applicable for scenarios where pure power supply is required and there is no need for signal transmission.

- Typical applications: Power supply for LED light strips, small DC motors, and simple sensors

- Product advantages: The Octopusconn 2 core M16 connector features gold-plated copper alloy contacts, resulting in low conductive loss. It is equipped with an IP67 waterproof sealing structure, suitable for long-term use of outdoor low-power devices. The housing is made of nickel-plated brass, offering excellent corrosion resistance.

- Selection tip: Suitable for pure power supply scenarios with a current of ≤ 7A and a voltage of ≤ 250V. When there is no need for additional signal transmission function, this option should be chosen as the first choice.

2PIN M16 connector and LED light strip power supply application

2. 3 Core M16 Connector: Grounded power connection scheme

- Core purpose: Power transmission requiring grounding protection, while balancing safety and stability.

- Typical application: Main power supply for industrial equipment, small water pumps, and electric valves

- Product advantages: The Octopusconn 3 model supports the "hot wire + neutral wire + ground wire" standard configuration. It has passed CE and ROHS2.0 certifications and features an anti-electric leakage protection design. It has a wide temperature operating range (-40℃ to +85℃) and is suitable for harsh industrial environments.

- Selection tip: This device is suitable for scenarios where grounding is required and the power output is moderate (3-5A). It helps avoid potential safety hazards caused by the absence of grounding.

3. 4-core M16 connector: Hybrid power and signal transmission input for door model

- Core function: Simultaneously meet the requirements of basic power supply and simple signal transmission.

- Typical application: RS485 communication equipment, ordinary sensors (temperature/humidity sensors), PLC basic module connection

- Product advantages: The Octopusconn 4-core M16 connector adopts A-Coding design, which has a remarkable anti-misinsertion effect. Some waterproof models support IP67 protection. Combined with high-shielding cables, it has outstanding anti-electromagnetic interference capability, and is suitable for basic connections in automated production lines.

- Selection tip: For scenarios where both 1 power supply and 1 signal need to be transmitted simultaneously, the core count is reduced and the cost is controllable.

4. 5-7 Core M16 Connector: The main model of the versatile combined transmission device

- Core function: Mixed transmission of multiple signals and power supply, suitable for complex control requirements

- Typical applications: PLC control cabinet expansion module, automated production line control node, multi-functional sensor group

- Product advantages: The Octopusconn 5-7 pin series supports custom pin assignment (power + 2-4 signal lines), has a plug-in life of over 500 times, the terminal adopts welding technology, the connection is very strong, and it provides straight/curved installation methods, suitable for different space layouts.

- Selection tip: For scenarios where multiple signals need to work together (such as "power supply + data acquisition + status feedback"), and where the transmission density is not high, this option offers the best cost-performance ratio.

5. 8-12 Core M16 Connector: High-density Signal Transmission Professional Model

- Core function: Multi-channel signal transmission + Medium power power supply, meeting the requirements of complex equipment.

- Typical applications: Joint connections for industrial robots, high-end detection instruments, multi-parameter sensor groups, main control nodes of automated production lines

- Product advantages: The Octopusconn 8-12 core M16 connector supports EMI shielding function, effectively suppressing signal interference. The pin spacing is reasonable, and the heat dissipation performance is excellent. It supports OEM/ODM customized pin definitions and is suitable for meeting the interface requirements of special devices.

- Selection tip: For high-end automation equipment and scenarios requiring multi-channel signal synchronization transmission, it is recommended to reserve 1-2 additional core lines to facilitate future functional expansion.

6.16-24 Pin M16 Connector: Ultra-high Density Transmission Premium Model

- Core application: Integration of multiple systems in large-scale equipment, and transmission of highly complex signals

- Typical applications: Large industrial robots, central control units of intelligent production lines, multi-module integrated equipment

- Product advantages: The Octopusconn 16-24 pin series features a reinforced metal casing with a protection level of IP67+. It supports high current transmission (up to 7A per pin) and is manufactured using precise molds, ensuring precise pin positioning. It meets the demanding connection requirements of high-end industrial equipment and the entire series has passed ISO9001 quality system certification.

- Selection Tip: This is applicable only to high-end scenarios with multiple systems and dense signal transmission. Avoid blindly pursuing high core counts, which may lead to cost waste.

Selection of Octopusconn M16 Connectors: 3 Key Principles

1. On-demand matching principle: Reject "excessive core count" and "insufficient functionality"

- First, clarify the transmission requirements: distinguish between "pure power supply", "power supply + signal", and "pure signal" transmission types, and list the mandatory functional items.

- Reserve additional expansion space: For regular scenarios, reserve 1-2 spare cores; for special equipment (with a service life of ≥ 5 years), reserve 2-3 cores. This is to avoid having to replace the connectors again during later upgrades.

- Reference case: An automated production line uses the Octopusconn 6-core M16 connector, which not only meets the current requirements of "power supply + 3 sensor signals", but also reserves 1 spare core. When the counting function is added in the future, it can be directly enabled without the need to modify the hardware.

2. Scene adaptation principle: The environment and installation conditions determine the selection direction.

- Environmental protection requirements: For outdoor/damp environments, the Octopusconn models with IP67/IP68 water resistance rating should be preferred. For salt spray environments, the stainless steel shell version should be selected.

- Installation space limitation: The curved installation model is suitable for narrow spaces, while the straight model is chosen for regular scenarios. For panel installation scenarios, a dedicated fixing nut should be used.

- Operating temperature range: For extreme high and low temperature environments (-40℃ or above or +85℃ or below), the Octopusconn wide temperature customized model can be selected to ensure stable operation.

3. Quality-first principle: Choose professional brands and certified qualifications

- Core parameter verification: Focus on key parameters such as protection level, insertion and removal lifespan, and temperature range, and avoid low-priced inferior products.

- Comprehensive certification: Choose products that have passed CE, ROHS2.0, and ISO9001 certifications. All Octopusconn M16 connectors in the series comply with international standards and their quality is traceable.

- Brand service guarantee: Preferentially choose brands with a complete after-sales system. Octopusconn offers 24-hour technical consultation, sample testing, installation guidance and other full-process services. Its global customer base covers five continents, and the delivery cycle is stable.

M16 Chip Count Selection Guide: Uncovering 4 Common Pitfalls and Solving Them

1

Misconception 1: The more cores, the better.

Risks: Increased costs, complex installation, higher probability of signal interference

Solution: Determine the number of cores based on "current requirements + necessary reserve". For example, when connecting a common sensor, 4 cores can be used, and there is no need to blindly choose 8 cores.

Octopusconn Solution: Offer free consultation services for equipment selection. Based on the equipment parameters and scene requirements, provide precise recommendations for the appropriate number of chips.

2

Misconception 2: Ignoring the matching of encoding types

Risk: Incorrect insertion of connectors of different codes (A/B/D, etc.) may cause damage to the equipment.

Solution: Uniformly select the same encoding model. The Octopusconn M16 connector defaults to using the industry-standard A-Coding. For special requirements, other encodings can be customized.

Notes: When making the selection, clearly inform the coding requirements to avoid procurement errors caused by mismatched codes.

3

Myth 3: Ignoring the compatibility between cables and core numbers

Risk: The cable's wire diameter does not match the number of cores, resulting in poor contact or inadequate heat dissipation.

Solution: Octopusconn provides matching cable components. The corresponding wire diameter is selected based on the number of cores (the range of outgoing wires is 4-6mm). For high-core-count models, multi-strand twisted wires are used to reduce signal interference.

Selection Tip: When purchasing connectors, it is recommended to pair them with original factory cables to ensure system compatibility.

4

Myth Four: Products with lower prices have higher value for money.

Risks: Poor material quality, ineffective protection, short lifespan, and high maintenance costs in the later stage.

Analysis: By comparing the core parameters with the brand's strength, Octopusconn uses high-purity copper alloy contacts and high-quality sealing components. Although the initial purchase cost is slightly higher, its average lifespan reaches 5-8 years, which is much higher than the industry average. Therefore, its long-term cost-effectiveness is even better.

Why choose the Octopusconn M16 connector?

1

Professional technical accumulation

With years of experience in the research and production of industrial connectors, the core team has rich experience in designing the M16 series products. They can quickly respond to the customized requirements of OEM/ODM.

2

Full-range coverage advantage

From 2 cores to 24 cores, from standard models to waterproof models and wide-temperature models, all product series meet the needs of different scenarios. One-stop purchasing is convenient and efficient.

3

Strict quality control

Full-process quality inspection is carried out from raw material procurement to product delivery. Each batch of products undergoes waterproof testing, electrical performance testing, and lifespan testing, ensuring stable and reliable quality.

4

Improve the service system

Offer full-cycle services including free sample testing, technical solution design, installation guidance, and after-sales maintenance. Our 24-hour consultation hotline responds promptly to customer needs.

5

Global market recognition

The products are sold far beyond to regions such as North America, Europe and Southeast Asia. They are widely used in various fields including industrial automation, energy, healthcare and transportation, and have received good reviews from customers.

Precise selection, starting with professional advice from Octopusconn

There is no absolute "optimal solution" for the core number selection of the M16 connector; only the "most suitable" option exists. By mastering the three principles of "matching as needed, adapting to the scenario, and prioritizing quality", combined with the technical support of professional brands, one can avoid making mistakes in the selection process.

Octopusconn, as your reliable partner, not only offers high-quality M16 connector products, but also strives to help you reduce procurement costs and enhance system stability through professional selection guidance and customized solutions. If you are struggling with the selection of M16 connector cores, please visit our company introduction page to learn more details, or contact us to obtain a personalized selection plan:

Company Introduction:

www.octopusconn.com

Consultation Method:

[sale@octopusconn.com]

Sample Application:

Detailed product drawings can be obtained.

Choose Octopusconn, and make the selection of M16 connectors more accurate, and ensure more stable industrial connections!